BRIGHT PHARMA MACHINERY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to BRIGHT PHARMA MACHINERY

Magnetic Mixer

CAPACITY :

20 to 10000 Ltrs.

TECHNICAL SPECIFICATION :

Complete vessel design as per ASME Code.

Instrumentation & connections comply with BPE & EHEDG guideline.

Vessel design & fittings / Stirrer are designed for CIP / SIP able.

OPERATION :

Complete aseptic design with Magnetic mixer & high shear Magnetic emulsifier.

Zero dead leg aseptic design Flush bottom outlet diaphragm valve with SIP able.

Sampling valve zero dead leg type with CIP/SIP able.

Volume monitoring by Load Cell.

PH Sensor / Conductivity Sensor provided on demand for online check Product

PH & Conductivity.

ADVANTAGES :

Free and clean working area around the charging port.

Variable speed drive allows to control of mixing speed while batch preparation.

Designed in accordance with cGMP requirements for CIP and SIP.

Mixing head designed for vigorous mixing or low volume blending.

Magnetically powered drive, NO SEALS / NO SHAFT thereby eliminating contamination.

Easy removable of drive unit.

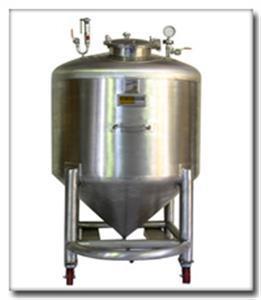

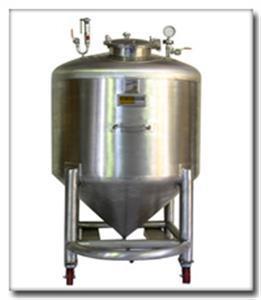

Fermentators

|

Pure Steam Generator

APPLICATION :

Used for Sterilization of vessel / Pipeline / Reactors & Inner chamber of Autoclave.

CAPACITY :

50 to 1000 Kg./hr.

TECHNICAL SPECIFICATION :

Purified water with max. conductivity of 0.5 micromhos/cm. should be used.

Pressure should be 1 kg/cm.sq. higher than the in feed steam pressure.

Temperature Ambient 30ºC.

Outlet of clean steam pressure 3 kg./cm.²

Ointment And Cream Manufacturing Plant

To prepare :

- Lotions

- Creams

- Gels

- Sterile & Non Sterile Ointments

Body Care and Cleaning

Lotions / Creams / Gels

Skin Protection Products-

Sun Creams and Lotions / Sun Gels

After Sun Products.

Hand Washing Paste

Liquid Soap

Hair Care Products -

Shampoos

Conditioners

Intensive Hair Treatments

Hair Dyes and Colorings

Other Cosmetics-

Tooth Paste

Deodorant stick paste

Mascara

Shaving Creams

Bath Additives

Foot care Products & Many more…….

CAPACITY :

25 to 3000 Kgs.

Cosmetic Shampoo Manufacturing Vessel

|

Aerosol And Inhealer Manufacturing Vessel

APPLICATION :

Used for HFA type product for Inhealer / Air Freshner.

CAPACITY :

10 to 500 Ltrs.

TECHNICAL SPECIFICATION :

Vessel design as per ASME SEC-VIII, DIV-I Pressure vessel with Agitator.

Zero dead legs valve for outlet.

Rapture disc for pressure safety.

Mechanical seal for stirrer to withstand high pressure.

Special design hopper for Powder charging.

Pneumatical operated lifting arrangement.

Special gasket / “O” Ring compatible with product.

Complete FLP design.

OPERATION :

Complete manual operation with FLP Panel

(Auto – Operation on demand.)

FEATURES :

Minimum stirring agitator with high pressure.

Vessel is CIP / SIP able.

Liquid And Oral Manufacturing Machinery Unit

APPLICATION :

Liquid – Oral Manufacturing Plant is designed as per present cGMP requirements to manufacture

Oral Liquid/ Suspension etc.

CAPACITY :

1000 to 20000 Ltrs.

PLANTS CONSISTS OF :

Sugar Dissolving Vessel.

Manufacturing Vessel.

Holding Vessel.

Online Sugar Syrup Pre Filter

Vacuum System for Transfer of Sugar & Sugar Syrup

Zero Holdup Filtration Unit.

Inline Homogeniser.

Inter connecting vessel / Sugar Suction Pipeline

Rotary Bottle Washing Machine

|

Volumetric Liquid Filling Machine

|

Packing Conveyor Belt

|

Multi Column Distilled Water Plant

APPLICATION :

To generate WFI water for injection / Large volume of Parenteral.

CAPACITY :

50 to 2500 Ltrs.

TECHNICAL SPECIFICATION :

Distillate -

IP/BP/USP specifications compliance.

Distillate Temperature 95ºC

Conductivity : Less than 0.5µ Siemens/cm.

Endotoxing – Less than 0.25 Eu./ml.

TOC – 100 PPB

FEED WATER

Purified water with max. conductivity of 0.5 micromhos/cm. should be used.

Pressure should be 1 kg/cm² higher than the in feed steam pressure.

Temperature – Ambient 30ºC

Dry Heat Sterilizer

APPLICATION :

To sterilize the Vials / Ampoules / Large parenteral bottles.

SIZE AVAILABLE :

Tailor made (As per Customer’s requirement)

TECHNICAL SPECIFICATION :

Complete unit made out of S. S. 304.

Double door with diagonally tightening lock and silicon gasket.

Interlocking arrangement and indicating lamp provided.

S. S. Tubular heaters.

Temperature – up to 300ºC.

Air circulation – Blower with hepa filter.

Hepa pressure module provided in air suction line.

Inlet / Outlet damper valve are pneumatically operated.

D.M. Water Storage Tank

|

Fluid Bed Dryer

APPLICATION :

To dry powder / Granules by Air Fluidization material.

CAPACITY :

30 / 60 / 120 / 250 / 300 / 500 Kgs.

TECHNICAL SPECIFICATION :

Monoblock Construction: Retarding chamber and expansion chamber are made in single piece construction to enhance cGMP and facilitate hygienic cleaning.

Filters bag sealing arrangement by means of inflatable tube

Interlocking between filter bag sealing tube and blower motor, and exhaust butterfly valve

Pre air filtration by 20 micron filters and secondary by 5 micron

Final air filtration through HEPA (0.3 micron) filters.

Double Cone Blender

APPLICATION :

To blending and mixing of Dry Powders / Granules and Crystals like Colors, Pigments, Minerals, Dyes, Flour, Grain, Ceramics, Detergents and other food, Pharmaceuticals & Chemicals powders.

CAPACITY :

10 Kgs. to 3000 Kgs. (Above capacity on demand)

TECHNICAL SPECIFICATION :

All contact parts are made out of 304 / 316 / 316 L quality material as required by the customer.

One shaft with fixed baffle inside the blender.

Tablet Multi Mill

APPLICATION :

Multi Mill is widely used for wet and dry granulation, Pulverisation etc. in Pharmaceuticals, Chemicals and various industries.

CAPACITY :

50 Kgs. to 200 Kgs./hr. (Depending upon the product and the reduction required in size)

TECHNICAL SPECIFICATION :

Unit consists of S. S. 304 / 316 / 316 L quality hopper and processing chamber

With beaters assembly, motor, reversible, switch, DOL starter, four speed step pulley, suitable screen with painted pillar mounted on base plate with castors.

Rotor Speed : 750 / 1500 / 2300 / 3000 RPM

Motor : 3 H.P./1440 RPM / 440 V. / 3 Phase / 50 Cycles / TEFC

Vibro Sifter

APPLICATION :

Vibro sifter are circular unitary gyratory screens used to separate mass composition of solids from solids, liquid from solid and for gradation of materials as per particle size, having a very wide range applications.

SIZE AVAILABLE :

12” / 20” / 30” / 48” 60” & 72” dia.

TECHNICAL SPECIFICATION :

All contact parts are S. S. 316.

Noiseless, Maintenance Free & High speeds.

Portable and compact.

Electric power requirement less than other machine of the kind in the industries & lower energy.

Consumption compared to reciprocating vibratory system.

Standard machine are with TEFC motor explosion proof / FLP motor.

Easy dismantling and cleaning facility for contact parts.

Rapid Mixer Granulator

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.